Marine Separator Applications

It’s surely the fact that Alfa Laval marine separators remove cat fines from 150 million tonnes of fuel each year. Or is it the energy savings and environmental compliance they secure? For a century, Alfa Laval has defined and pushed the boundaries for what a marine separator can achieve.

Today our separators serve over 50% of the world fleet, handling both traditional and new fuels, but also lube oil, waste oil, bilge water, crankcase gas and scrubber water. Customers turn to us for application leadership, while our global service network is what they count on for parts and peace of mind.

The right product for your application

Alfa Laval separators have a key role to play in solving the most important cleaning challenges in the marine industry.

Oil cleaning

Alfa Laval S and P separators protect your engine and other equipment from impurities such as cat fines.

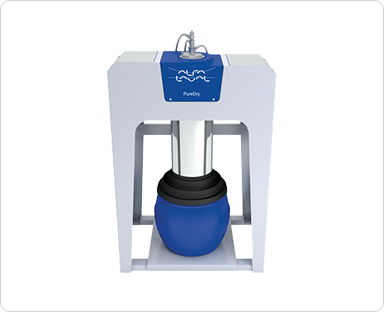

Waste fuel recovery

Alfa Laval PureDry can recover reusable fuel from waste oil – and eliminate wet sludge for disposal.

Bilge water treatment

Alfa Laval PureBilge provides bilge water compliance in any conditions – without filters and waste.

Crankcase gas cleaning

Alfa Laval PureVent removes oil and particles from crankcase gas, removing an overlooked source of emissions.

EGR water treatment

Alfa Laval PureNOx Prime supports Exhaust Gas Recirculation (EGR) by effectively cleaning process and bleed-off water.

Marine service network

Our dedicated Marine Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment.

How can we help you?

Please contact us for questions and service requests.

For marine emergency service, please call +46 4636 7700.

Meeting industry challenges

Alfa Laval’s separation expertise goes far beyond the separators themselves.

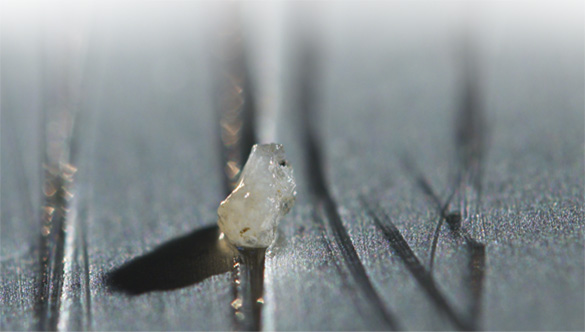

Cat fines

Centrifugal separators are the best line of defence against cat fines, and their protection can be made even more effective. Flow optimization of the separator feed improves separation efficiency while saving a great deal of energy – not only in the pumps, but also in the separator itself.