Revos draft dispense

The Alfa Laval Revos™ draft dispense is a compact, post-mix dispensing system that rehydrates beer and beverage concentrates at the point of consumption. With Revos draft dispense, beer and beverage manufacturers can realize significant logistics and supply chain cost savings when storing and transporting concentrates in bulk, then reconstituting it moments before serving cold draft beer and beverages at pubs and restaurants.

Reduce costs and boost your sustainability profile serving draft beer, cider and wine from concentrate on tap

- Reduce transport costs by up to 65% due to reduced storage and shipping volumes of concentrate throughout the supply chain to the consumer

- Serve up five to 10 times the beverage from concentrate, taking up less storage space than the original product

- Free up space under the counter, yet store and dispense more beverage than a single-keg kegerator

- Improve workplace safety and reduce manual labour by eliminating frequent changeout of kegs while dispensing beer or beverage from concentrate

- Improve quality assurance – visible to consumers – with real-time monitoring of temperature, carbonation and concentration for every single pour

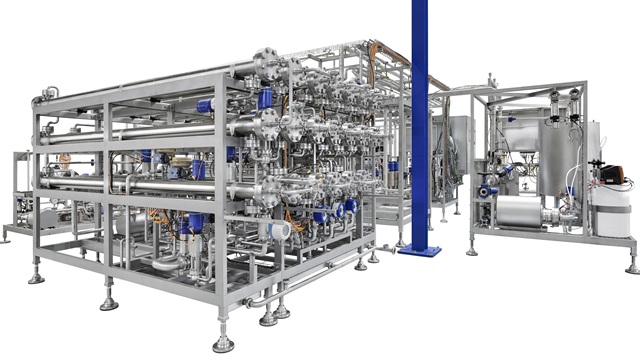

Alfa Laval Revos draft dispense is a compact, post-mix draft dispensing system. It reconstitutes beer and beverage concentrates that match the flavour profile of the original product at the point of sale.

Get a fully fermented or non-alcoholic beer and beverage concentrate from patented Revos™ reverse osmosis technology. Drastically cut costs and emissions by transporting concentrate in bulk and then precisely rehydrate the beverage with pure, carbonated water –either directly at the point of sale or at regional packaging plants with Revos draft dispense systems.

Part of Alfa Laval’s broad solutions portfolio for the of brewery and beverage industries, Revos draft dispense helps brewers, beverage manufacturers and their customers meet sustainability targets by streamlining logistics and supply chains and reducing costs.

Alfa Laval Re-draft system monitoring

Ratio Control/Tracking

- Responds dynamically to changes to ensure a consistent pour

- Accounts for flow variability at the start of the pour and when water flow rate or pressure changes

Quality

- Keeps beer and beverages cold at all times

- UV sterilization prevents microbial growth after chlorine removal

Touchscreen display

- Makes data about each pour and keg and CO2 volumes available to bar staff

- Provides data about cleaning, calibration and maintenance available to service professionals

Alarms

- Alerts staff to change kegs, replace CO2 or call for service

- Recognizes issues with the machine or inputs

- Helps prevent off-spec pouring

Connectivity as a service

Remote monitoring and logging ensure

- Each pour is in spec

- Cleaning on track

- Usage analytics available to the brewer or manufacturer

Products

Alfa Laval Re-draft dispense system versus traditional draft

Protecting traditional experience

- Cleaning frequency and chemicals

- Great taste

- Pouring experience (appearance/rate/tap)

Consistent ABV, CO2 and foam level in every pour

Added benefits

- The Re-draft system lets you know pour specs/keg volume

- Self-cooling or integrated into a glycol system

- Recycle kegs/no return or cleaning

Same great taste, less volume

The Re-draft system supplies the same volume as traditionally packaged beer from a reduced-volume concentrate. Handling smaller volumes of concentrate increases workplace safety and reduces injuries. It also does away with the need to store kegs in refrigerated cold rooms onsite at the bar or venue.

How it works

Alfa Laval Re-draft system reconstitutes beer concentrate at the point of sale. It purifies and blends cold carbonated water with the concentrate, delivering a cold draft product on tap.

Pilot testing and rentals of beer concentration systems

Pilot testing and rentals of beer concentration systems

Test the Alfa Laval Revos concentration system and Re-draft system to determine whether these systems meet your requirements. Send up to 10 hl of your product to the Alfa Laval Revos Innovation Centre in Denmark for onsite testing and performance analysis. A Re-draft system is available for demonstration and testing to rehydrate the concentrate produced.

Alternatively, you can rent a Re-draft system and conduct trials reconstituting your beer concentrate at your facility or in a commercial setting.

Services

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems