Design your evaporation system for maximum benefit

Evaporation is used in many bio-based chemical plants, and is often the position which consumes the most energy. Choosing the right evaporation system not only minimizes energy consumption, but also reduces investment costs and improves product quality.

Minimize energy consumption

Energy costs are a major part of most chemical producers’ budgets. As energy prices are predicted to rise over time, plant energy efficiency is crucial to staying competitive in the marketplace.

There are several different ways to reduce energy consumption in an evaporation system, including:

- Using multiple effect evaporation

- Thermal or mechanical compressors

- Preheating with waste heat from the evaporator itself.

When designing an evaporation system, a balanced approach is recommended, where the costs and savings that come with different options are analyzed. As an example, adding more effects saves operating costs, but often requires a larger investment in more equipment. In addition, mechanical compression of the vapor comes at a lower operating cost than thermal compression, but the investment cost is higher.

Alfa Laval can help design the optimal evaporation system for your plant. We analyze a number of factors such as production rate, product price and steam cost to work out the perfect balance between investment and operating costs from a lifecycle perspective.

Reduce investment costs

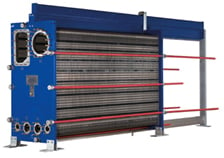

Some competitive solutions need several floors of space, extensive piping, and large recirculation pumps. When designing and installing Alfa Laval evaporation systems, the lower AlfaVap and overall system height makes it possible to install in one floor with small pumps (or even without). The result in significantly lower installation, building and equipment costs.

Improved product quality

The low hold-up volume in the AlfaVap system means the product has a short residence time in the evaporation system. The benefit is minimized product degradation due to high temperatures, and results in a higher quality end product. The low hold-up volume also ensures fast and smooth start-up and easy process control.

Whitepaper: 10 ways to improve your bio-based chemical plant