TJ40G-HD

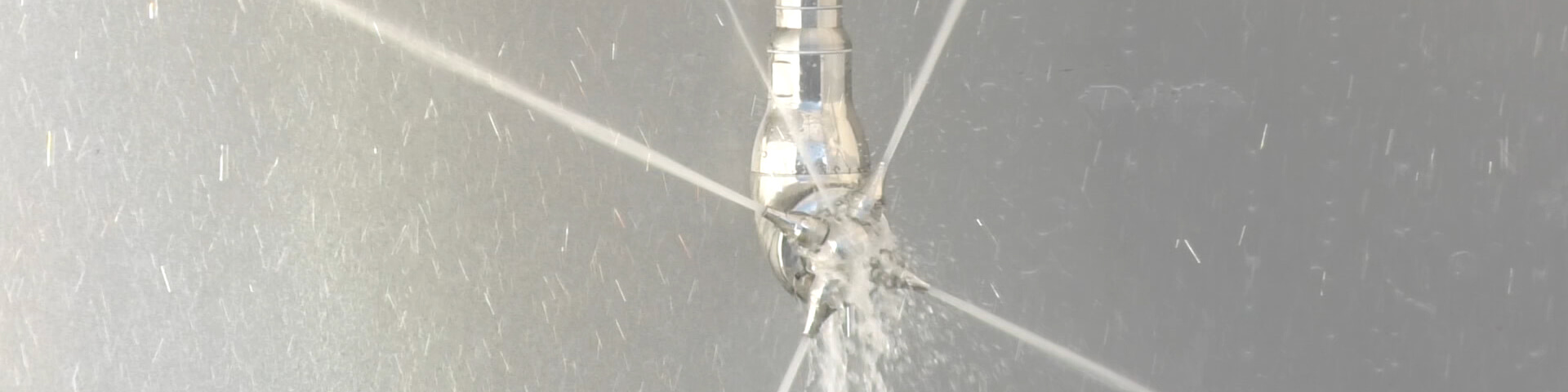

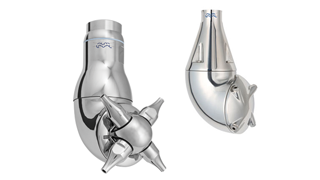

Rotary jet head tank cleaning for heavy-duty applications

High impact quality assured cleaning in a 360° repeatable cleaning pattern

- Avoid contamination with effective cleaning performance and superior self-cleaning features

- Cost efficient and sustainable solution reduces cleaning costs by up to 70% (water and chemicals)

- More available production time with up to 60% faster cleaning times

- Easy to service and maintain – no special tools required

- Control of CIP through validated cleaning

The Alfa Laval rotary jet head TJ40G-HD is for applications where larger amounts of particles in the cleaning liquid are re-circulated over the machine. Its special design ensures that particles do not get trapped inside the machine or damage / block the machine during operation.

Effective tank cleaning with low operating costs

The Alfa Laval tank cleaning machine is a orbital cleaner that has a strong jet that generates a high mechanical force and covers 360° to efficiently remove remaining products and residues and provide the best hygienic conditions for production. As the force generated by the rotary jet head tank washer increases, the water consumption decreases, which leads to significant cost savings as illustrated in the diagrams. (based on Dr. Sinner’s cleaning philosophy.

- Cost savings (water, chemicals): 70%*

- Time saving = more production time: 60%*

*compared with traditional static spray ball cleaning

Static Spray Ball

Blue = Water consumption/time

Red = Mechanical action

Alfa Laval TJ20G / TJ40G

Yellow = Temperature

Grey = Chemicals

Blue = Water consumption/time

Red = Mechanical action

Yellow = Temperature

Grey = Chemicals

Learn more

You can read more about the efficiency, practicality and technical details of the TJ40G Rotary Jet Head tank cleaning devices.

How it works

How does the TJ40G work? Click here to find out.

Validate your tank cleaning process

Alfa Laval Rotacheck validates the rotary jet heads cleaning process, reduces water consumption and product loss. Provides peace of mind.

Reducing Your Cleaning Time to Produce More Beverages

Today’s beverage market is much more demanding than it once was. How do you overcome the challenge of rapid Cleaning-in-Place optimization in your beverage production line?