Flexitherm

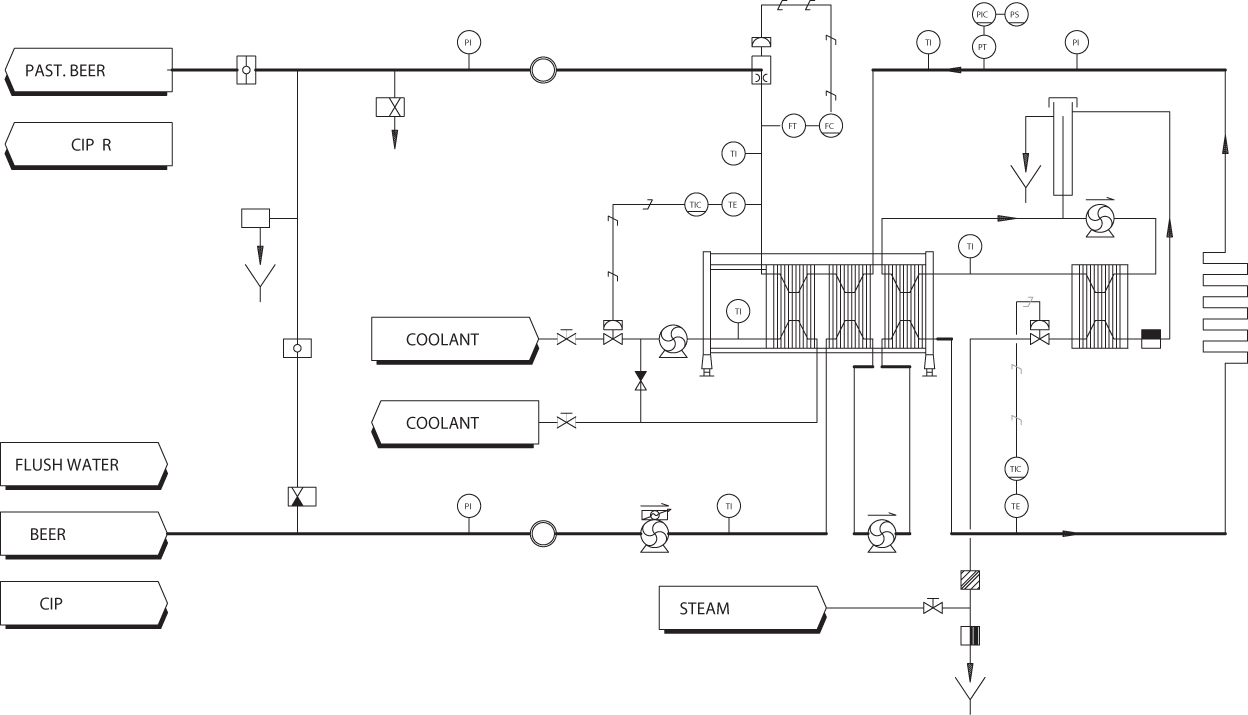

Flexitherm™ is an automatic pasteurization machine for beer pasteurization. Flexitherm™ uses a pasteurization method that eliminates microbiological spoilage, achieves the right pasteurization temperature and preserves the quality and shelf life of beer and other carbonated drinks over a variable flow range. This pasteurization method is tailored to provide optimal, efficient thermal treatment of beer to be sent to aseptic filling systems.

Reduce microbiological spoilage and preserve beer quality

- Reliable pasteurization units (PU) control system for stable product treatment (PU variations within +/- 10% of target level during constant operation

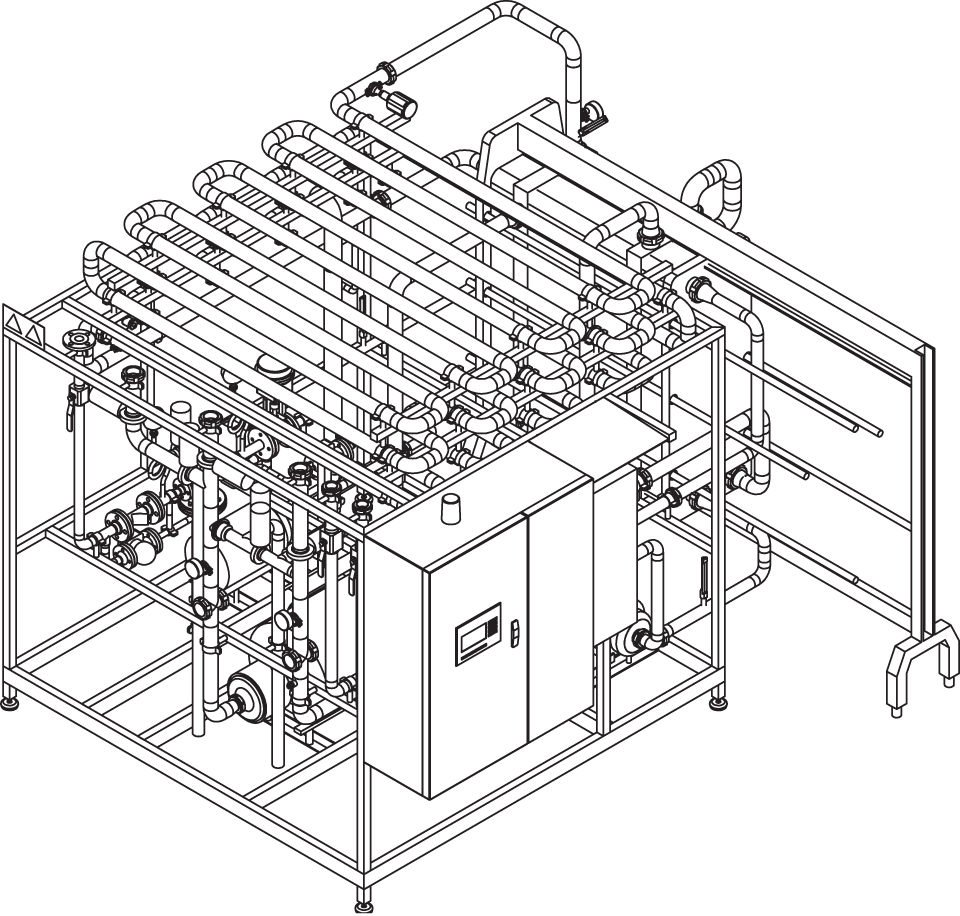

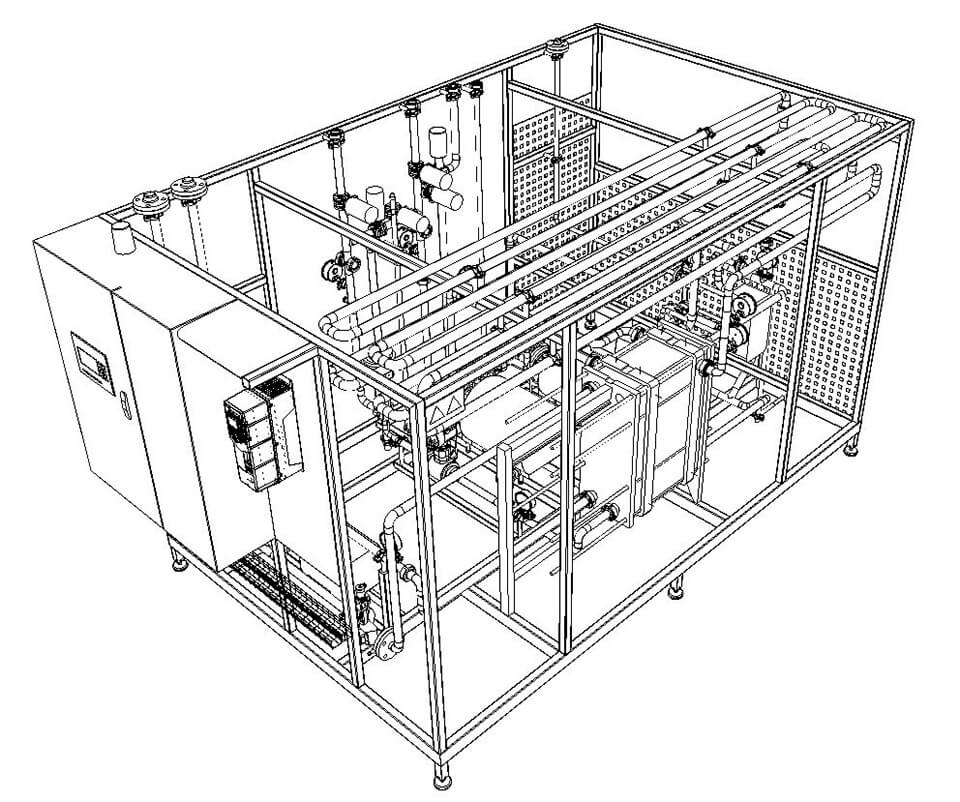

- Minimum site work as the module is self-contained and pre-assembled with automatic control

- Designed for CIP, the sanitary and compact module requires low maintenance, minimizing downtime

- Effective energy recovery up to 95%

- State-of-the-art automated control system featuring process continuously refined control refinements

Flexitherm™

Flexitherm™ is a well-proven concept for high capacity brewery processing. It cuts operation costs by recovering up to 95% of heat*.

Specification

Approximate dimensions and weight depending on capacity range:

For capacity = 40hl/h,

Dimensions (LxWxH): 3.2m x 2.0m x 2.2m

For capacity = 400hl/h,

Dimensions (LxWxH): 4.0m x 3.6m x 2.6m

*Compared to a traditional tunnel pasteurizer, it improves overall water consumption by up to 0.42hl/hl, and improves the energy usage ratio by 5MJ/hl.

Learn More

Read our product brochure to learn more about this product's application, working principle, benefits and technical details.

Flexitherm™ Mini

Designed especially for craft brewers, Flexitherm™ Mini lets you save several recipes in the same unit with individual settings for different craft beers.

Specification

Capacity: 5-50 hl/h (3 different modules)

Dimensions (LxWxH): 4,000 x 2,000 x 2,000 mm

Ready to take your beer to the next level

Fill out a few simple questions about your operation, and our craft beer experts will follow up soon with a quote for Flexitherm™ Mini.

How it works

Alfa Laval Plate Heat Exchanger for beer pasterurization

FLEXITHERM is a plate heat exchanger (PHE): A system for pasterurization of beer which eliminates or reduces the number of live micro-organisms in the product. It reduces microbiological spoilage and improves microbiological stability and increases product shelf life.

Achieving the right pasteurization temperature with Flexitherm™

Flexitherm™ achieves the required pasteurization temperature through a combination of heat and holding time. Cold, unpasteurized beer is heated in the PHE to the desirable pasteurization temperature in two steps. Automatic adjustment of FLEXITHERM flow to cater for variations in filling machine demand. Avoid product recirculation and risk of over pasteurization.