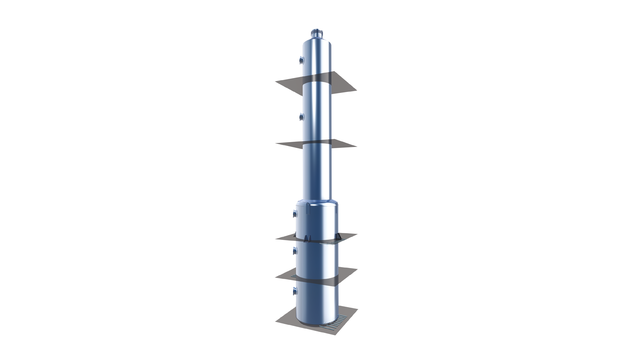

SoftColumn

Deliver consistently high-quality edible oils without unwanted flavours and odours. The Alfa Laval SoftColumn™ is a patented and energy-efficient system that optimizes the deodorization process while preserving flavour, aroma, colour, and shelf life. Using gentle heating, this edible oil deodorizer effectively removes impurities. Optimizing the deodorization process of edible oil results in clean, stable products, lower operating costs, and the consistent quality your customers expect.

Boost efficiency with an advanced deodorization system

- Achieve target organoleptic properties while maximizing shelf life

- Cut energy and steam use by optimizing heat recovery and reducing temperatures to reduce costs

- Deliver clean, stable, consistently high-quality oils by removing free fatty acids, pigment and volatile compounds

- Scale production easily, adapting to different oils and production volumes with new plants or retrofitting existing lines

- Drive innovation with advanced, patented thin-film technology for improved efficiency and performance

The deodorization process is crucial to producing high-quality edible oils by removing unwanted compounds, odours, flavours, and volatile impurities. To stay competitive, producers must rely on the latest technologies to maximize product quality and processing efficiency.

Alfa Laval’s patented thin-film deodorization system is a significant advancement in the deodorization of edible oil. This innovative edible oil deodorizer improves thermal treatment while reducing operational costs. Its low-temperature operation requires less steam, helping to preserve oil quality and stability.

The SoftColumn™ deodorization system features separate stripping and retention sections, providing flexibility to handle different oil types, product specifications, and production capacities – whether installing a new system or retrofitting an existing one.

How the deodorization process of edible oil works

The deodorization process removes unwanted odours, flavours, and impurities, improving the oil quality and shelf life. It begins with deaeration, which removes the air to prevent oxidation. The oil is then gently heated using heat recovered, improving energy efficiency. In the deodorization system, the oil passes through stripping and retention sections under vacuum and steam, removing volatile compounds such as free fatty acids. Cooling and polishing filtration then produce a clean, stable, high-quality final product. The process is key to delivering safe, appealing edible oils for both food manufacturers and end consumers.

The deodorization process starts with deaeration

Before heating the oil, air must be removed under vacuum (deaeration) to protect product quality by preventing oxidation. After leaving the deaerator, the oil is regeneratively heated in a special heat exchanger, an economizer, using the hot oil leaving the deodorization column to recover as much heat as possible. The oil then passes through a final heater, reaching the precise temperature required for deodorization, typically using high-pressure steam.

Stripping and retention in the deodorization system

Once at the designated temperature, the heated oil enters the deodorization column, the core of the deodorization system. The column may include a stripping section and a retention section. The oil passes through the stripping section under vacuum, and steam removes volatile impurities, including free fatty acids (FFAs) that have a higher vapour pressure than the main components of the oil itself. If present, these volatiles can affect the flavour, odour, and stability of edible oils.

The oil then resides in a retention section for a specified period of time for thermal treatment known as heat bleaching to remove undesirable pigments and ensure the stability of the final product. The duration in the retention section depends on the desired product specifications.

Condensing removed impurities

Volatile impurities removed during the deodorization process are condensed in a scrubber using cooled, recirculated distillate. The scrubber may be placed on top of the stripping section or installed as a separate unit.

Final cooling in the deodorization process

Here, the oil undergoes two-stage cooling. It is cooled in the economizer to achieve the specified final temperature and then undergoes polishing filtration. It is then transferred for subsequent processing, storage, or packaging

Expert article

Elevate the performance of your edible oil refining systems

Resource-smart production is essential as edible oils play a critical role in global food security. Optimize your processes over the entire lifecycle of your edible oil systems with the Alfa Laval service portfolio.

Leverage our full range our services - from system design, precision engineering, and effortless installation to commissioning, cost-effective operation, routine maintenance, and system upgrades.

With tailored service agreements, you can reduce waste, safeguard product quality, simplify operations, and maximize your return. Focus on the growth of your business while our global network and local providers take care of the rest.