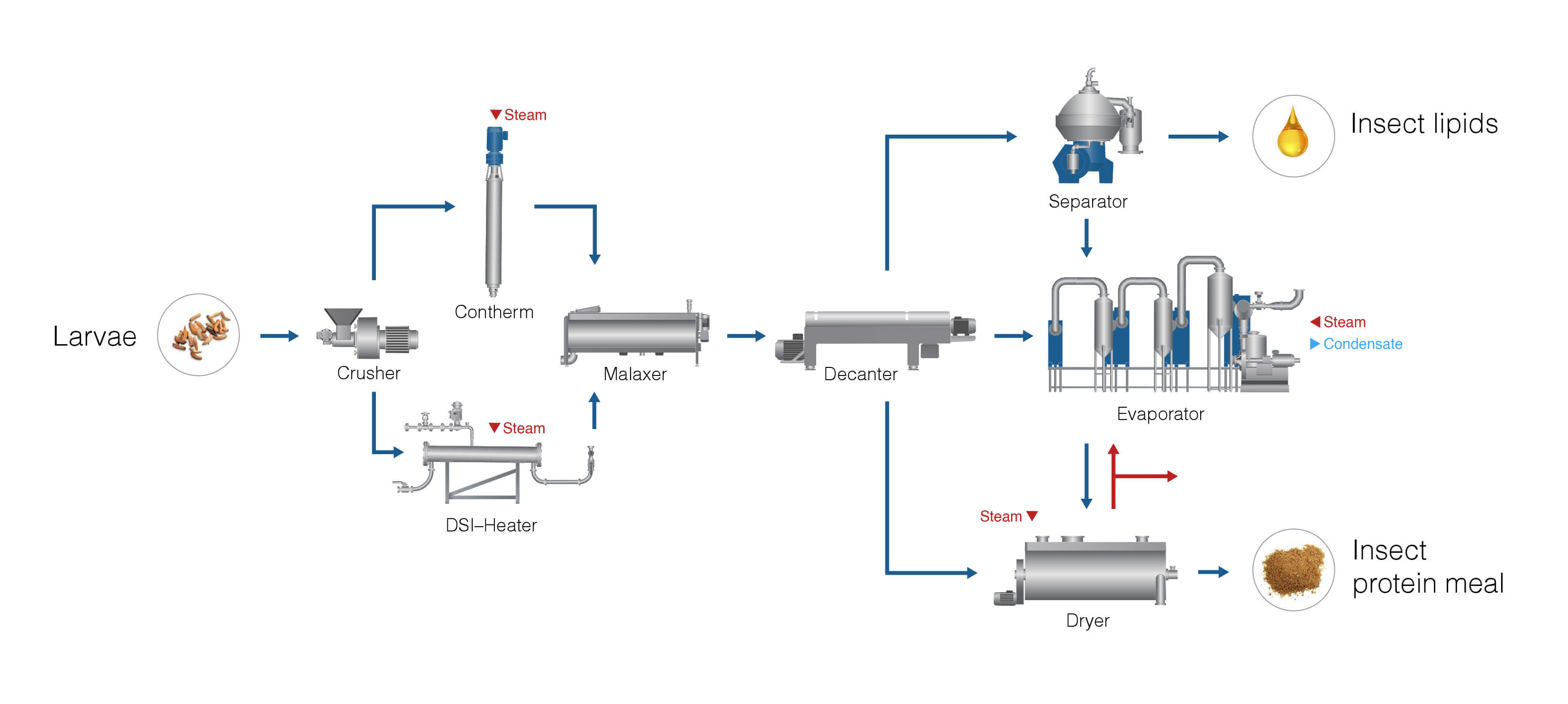

Insect protein meal and lipids processing – wet rendering

Process overview

Alfa Laval wet rendering systems – the facts

The main processing steps in a wet rendering process are

- Raw material preparation

- Heating of the raw material

- Separation of lipids, protein, and stickwater in a decanter centrifuge

- Purification of the lipids in a centrifugal separator

- Recovery of soluble proteins from the stickwater in an evaporation system

- Final drying of soluble and insoluble proteins in a dryer

- Processing capacity: From 400 kg/h

- Lipids purity: >99%

- Insect meal: <10% lipids and low moisture level

- Maximum processing temperature: 95°C (203°F)

- Retention time: ≥ 2 min

- Required floorspace: 260m2 (1-5 t/h)

Preparation and heating of the raw material

Various insects can be used as raw material, the most common being black soldier fly larvae, crickets, and mealworms. The first processing step is to cut the raw material into small pieces to improve pumpability and facilitate processing in the subsequent heating and separation stages.

Thereafter the raw material is heated using one of two methods:

1. Steam injection

Here the steam is directly injected into the raw material in a DSI heater, while the product is constantly agitated as it moves through the unit.

Steam injection is an efficient method to heat the raw material, requiring just a few minutes. The short heating time minimizes the thermal impact on the product, which improves the end-product quality. Furthermore, the injected steam helps reduce fouling and wash out the lipids from the larvae purée, which reduces lipids content in the final meal.

2. Indirect heating

When indirect heating is used, the larvae purée is heated in an Alfa Laval Contherm scraped surface heat exchanger without direct contact with the steam. The heating is completed in just a few minutes, and rotating blades in the heat exchanger continuously agitate the purée to ensure high thermal efficiency. The rotating blades also help minimize fouling on the inner surface, thereby extending uptime.

Comparing steam injection with indirect heating

The main difference between steam injection and indirect heating is that the steam never comes in contact with the product when indirect heating is used. Using steam injection means extra water is added, which must be removed in the evaporation stage, adding to both water and energy costs, which is avoided when using indirect heating.

A second key benefit is that a Contherm unit is more hygienic than a DSI heater, allowing you to meet the requirements in the most stringent standards.

A benefit of steam injection is that CAPEX is lower, and the separation of the lipids fraction is more efficient, leading to increased lipids yield and lower lipids content in the insect meal.

Both methods result in significantly higher product quality compared to dry rendering since the product is heated to a lower temperature and is exposed to heat for a much shorter time. Contact us for a discussion on what method suits your needs best.

Separation of lipids, protein and stickwater

After heating, the purée is separated into three fractions in one or two decanter centrifuges:

- Protein (solids)

- Lipids (liquid)

- Stickwater (water with soluble proteins)

Due to a special configuration of the decanter, enabling operation with a deep pond, the separation effectiveness in an Alfa Laval’s Foodec decanter is very high. The low water content in the solids fraction after separation reduces the energy consumption in the subsequent drying stage, and, in turn, energy cost, as well as investment cost for the dryer and the boiler. The low lipids content in the insect meal raises its market value and your profitability.

The effective separation also means the lipids fraction is very clean directly after the decanter, meaning the downstream centrifugal separator can be smaller, resulting in lower CAPEX and OPEX.

The decanter can be equipped with a fully automatic CIP cleaning system for quick and easy cleaning of both the inside and the outside.

Purification of the insect lipids

The lipids fraction is purified in a separator, taking out fine solids and residual water from the product.

Our Clara and AFPX separators can purify the insect lipids to the highest standards, and also reduce the lipids content in the stickwater to increase the value of the by-products. Thanks to the exceptional separation performance, the processed lipids contain minimum moisture, resulting in a higher market value and long shelf life.

Alfa Laval’s separators are characterised by gentle product handling, excellent corrosion resistance, outstanding hygiene, and low operating costs.

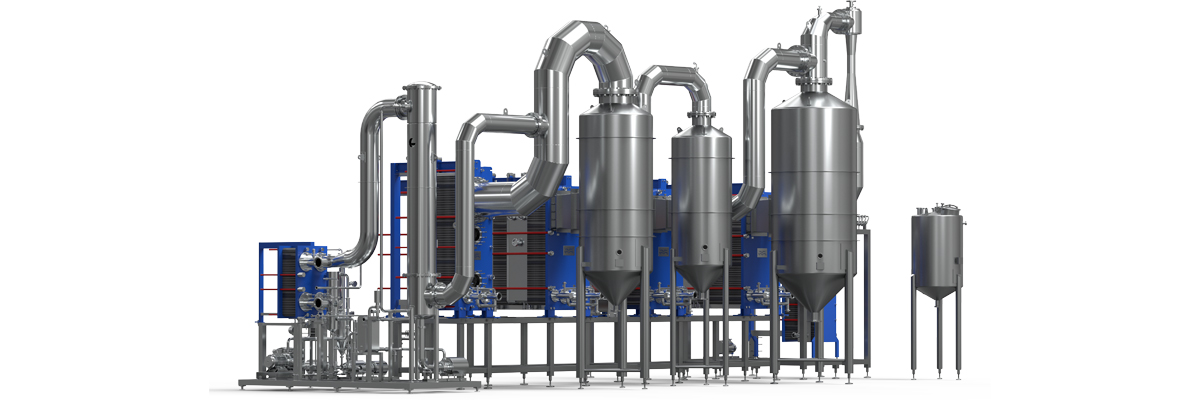

Recovery of protein from the stickwater

The stickwater is sent to an evaporation system where the water is removed, and the soluble protein is concentrated. Since 10-15% of the total protein content is in the stickwater, recovering it greatly impacts the overall process yield. The soluble proteins have better digestibility than the proteins in the solids stream, so by recovering them, the digestibility of the final meal increases.

Concentrating the stickwater also means less wastewater must be processed, and the separated water can be recycled and reused, thereby reducing the total water consumption.

Alfa Laval’s AlfaVap and AlfaFlash plate evaporation systems are ideal for concentrating insect stickwater. AlfaVap is intended for low-to-medium fouling processes, and AlfaFlash is for highly fouling applications.

They are available in multiple configurations and can run on:

- Steam

- Steam with a thermal vapor recompressor,

- Electricity with a mechanical vapour recompressor

- Waste heat from the dryer, enabling boiler savings of up to 100%

Alfa Laval evaporation system often comprises several evaporation stages (or effects) for efficient energy reuse, thereby minimizing energy consumption.

AlfaVap and AlfaFlash evaporators can handle more concentrated product streams than most other evaporation systems, allowing you to concentrate the stick water more and thereby lower the load on the dryer, leading to substantial energy savings.

AlfaVap and AlfaFlash are very flexible systems that allow for easy expansions, either by adding new cassettes in the plate heat exchanger or entire effects. Moreover, the high thermal efficiency makes the systems very compact, reducing installation costs.

Read about AlfaVap evaporation Read about AlfaFlash evaporation

Final drying of the insect meal

The solids from the decanter and the concentrated stickwater from the evaporator are mixed and dried in the dryer.

Different drying technologies can be used. Disc dryers, fluidized bed dryers or air dryers are commonly used in this application.

Using a disc dryer makes it possible to reuse the waste heat in the evaporator, thereby lowering operating costs. However, disc dryers are not food-grade equipment.

Insect meal processing systems

We offer complete wet rendering systems in all sizes, from pilot to full scale, and for all types of insects.

Our protein processing experts have long experience in designing protein rendering systems and optimizing them on a component, module, and system level. Contact us at an early stage in your project to get valuable advice when selecting equipment or designing your process line.