Catalytic reforming

Energy-efficient conversion of low-octane naphthas into blending components for high-octane gasoline is key to mogas-producing refineries. The most critical heat recovery position involves preheating the naphtha feed using reactor effluent. A single Alfa Laval Packinox heat exchanger maximizes energy recovery using minimal plot space, and its low pressure drop makes it easy to increase capacity.

Optimizing catalytic reforming processes at refineries

Alfa Laval compact heat exchangers bring high efficiency, compact size, minimum maintenance, low pressure drops and the ability to operate at high pressures and temperatures to refineries around the world.

Energy efficiency

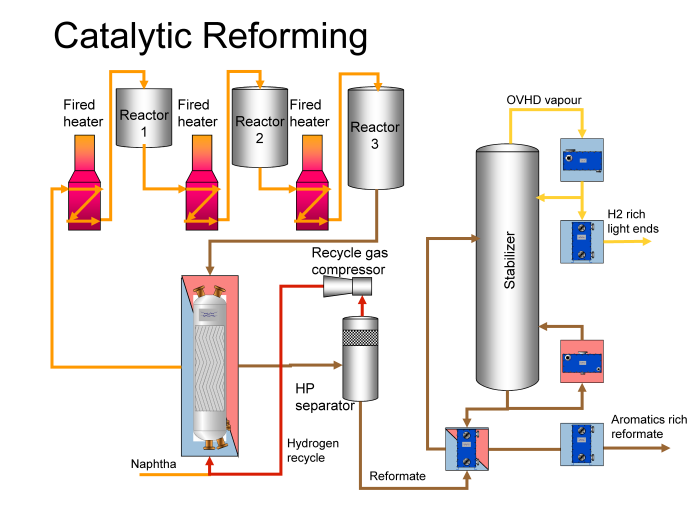

The catalytic reforming process consists of a high temperature reaction section and a low temperature reformate recovery section.

Reaction section

Recovering energy from the reactor effluent for use in preheating the reactor feed is one of the largest and most critical heat recovery duties in a refinery. A single Alfa Laval Packinox heat exchanger, designed for a hot end temperature approach of close to 10°C, can reduce energy consumption in the fired heater by more than 50%. The use of several shell-and-tube heat exchangers or Texas Towers would not be able to recover the same amount of energy.

Reformate recovery section

There are also opportunities to recover energy in the fractionation section that minimize both the operating costs and the environmental footprint of the process.

One such service is the reformate splitter feed/bottoms interchanger. To minimize the cost and size of the heat exchanger, this duty is usually designed with limited heat recovery.

With Alfa Laval Compabloc heat exchangers, it is possible to maximize energy recovery here, thereby minimizing energy requirements in the splitter reboiler duty as well as the cooling requirements of the reformate cooler.

Increasing capacity of catalytic reforming processes

Capacity bottlenecks can occur in the fired heater or the hydrogen recycle compressor of older catalytic reforming units.

By replacing existing combined feed/effluent heat exchangers with a single Alfa Laval Packinox heat exchanger, recovering more energy at a lower pressure drop, it is possible to offload both the fired heater and the compressor, thereby increasing capacity by up to 33%.

Replacing the traditional shell-and-tube heat exchangers in the reformate recovery section with Alfa Compabloc exchangers can also boost capacity and maximize energy recovery, further offloading this section of the process.

Minimizing CAPEX

A single, compact Alfa Laval Packinox heat exchanger can do the job of several large shell-and-tube heat exchangers.

To estimate the installed cost of the Packinox exchanger, a factor of maximum 1.5 is typically used rather than the factor of 3 that is typically used for shell-and-tube heat exchangers. This translates into a cost savings.

Further cost savings are possible when using Compabloc exchangers in heat recovery applications instead of several large shell-and-tube heat exchangers in series. This is also true when using Compablocs as overhead condensers, where minimal plot space and flooded weight are key factors in minimizing installed cost.

Proven technology for catalytic reforming processes

Alfa Laval has delivered some 300 Packinox heat exchangers for catalytic reforming to refineries around the world. In fact, using Packinox heat exchangers in grassroots catalytic reforming plants is even considered an industry standard. What’s more, Alfa Laval Compabloc heat exchangers also are at work in catalytic reforming and benzene saturation units around the world as stabilizer feed/bottoms interchangers, stabilizer condensers and reboilers and reformate final coolers.